Food and Beverages

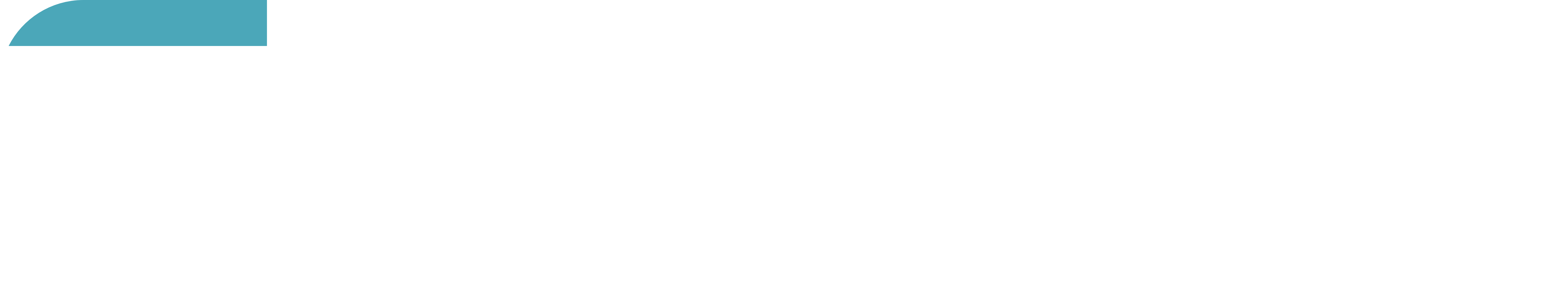

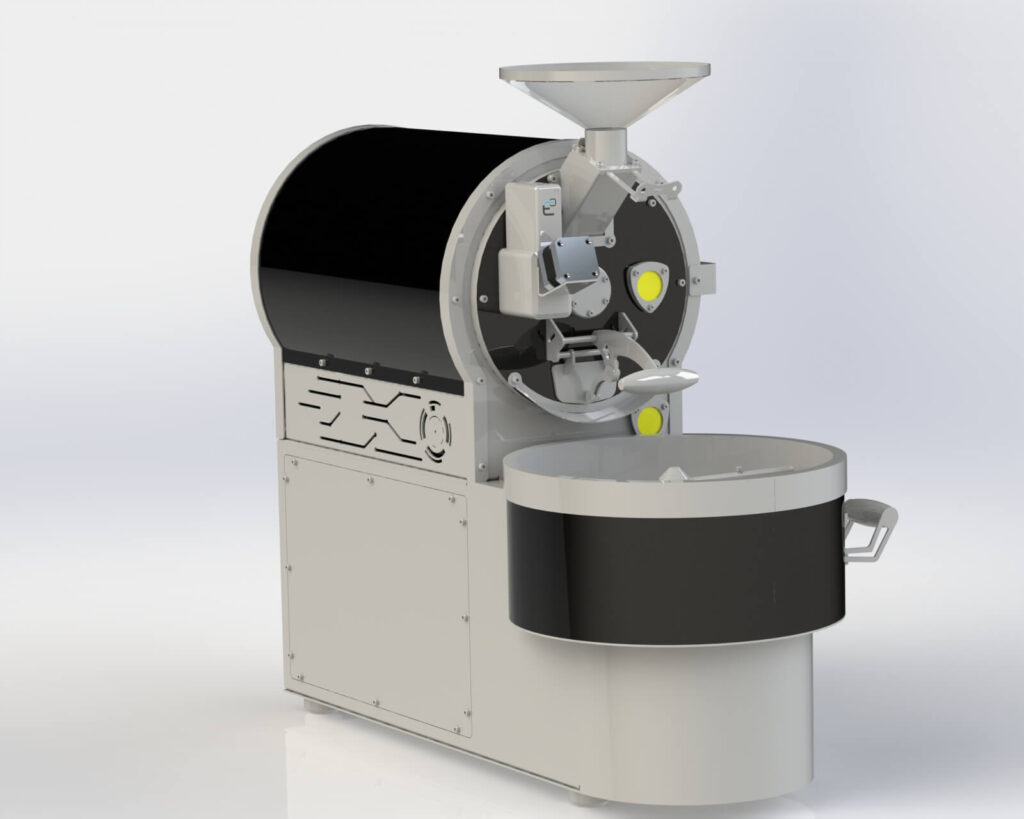

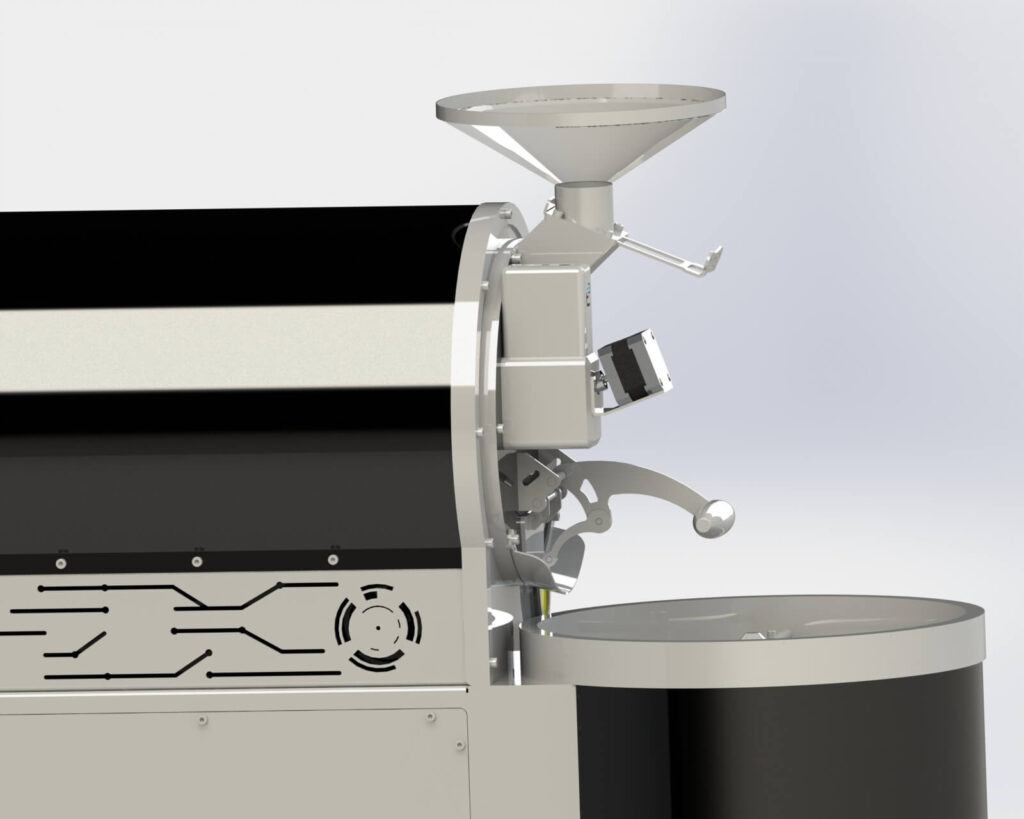

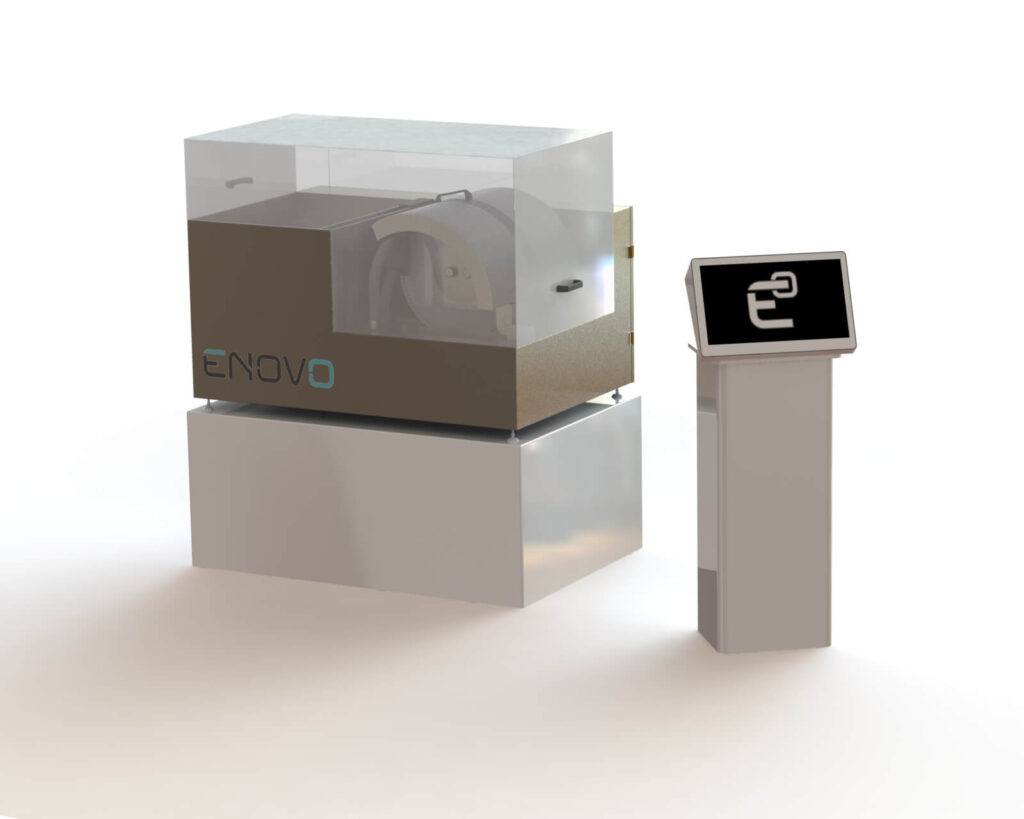

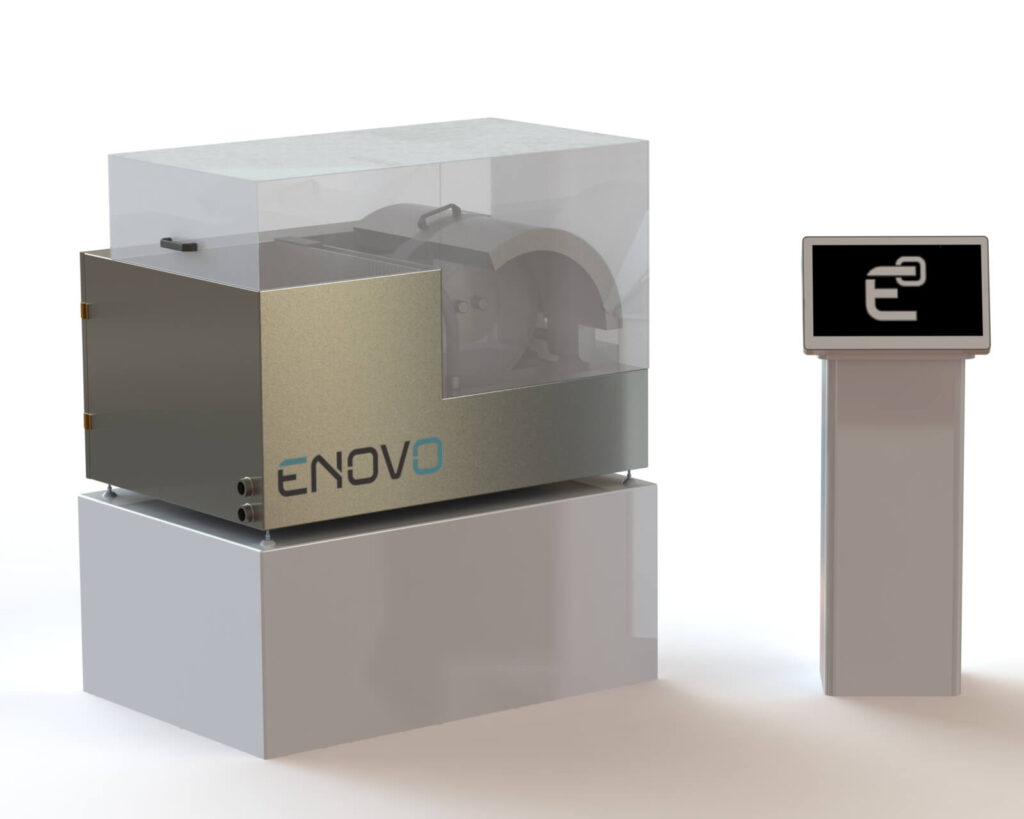

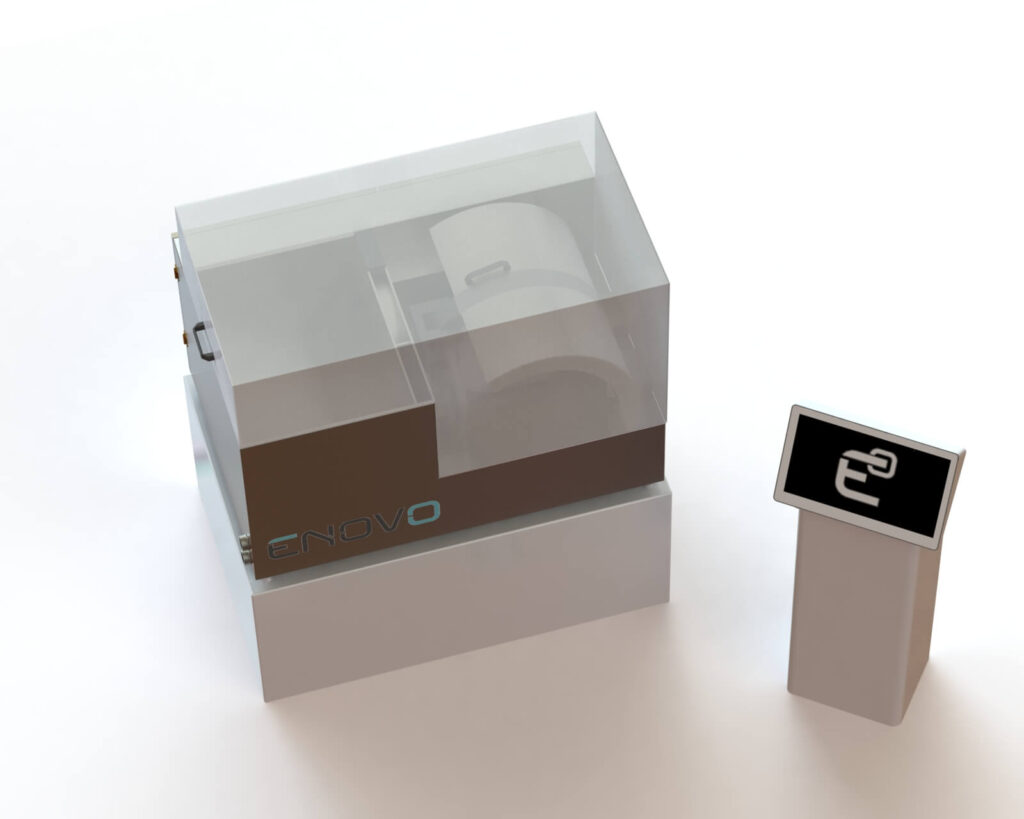

Coffee beans inspector

Embark on a journey through the intricacies of our groundbreaking machine, made to redefine the art of bean roasting assessment. Machine vision and software, our advanced technology delves into the minutiae of temperature monitoring, employing sophisticated algorithms to analyze the bean’s roasting status with unparalleled accuracy.

From the moment the beans enter our system, they are subjected to a meticulous examination process, where our cutting-edge sensors assess their temperature and appearance. Through seamless integration of machine learning algorithms, our AI-driven solution adapts in real-time, continuously refining its roasting assessment capabilities to ensure optimal results.

FoodSense AI inspector

Introducing our latest innovation in food inspection technology: the FoodSense AI Inspector. Designed for the food industry, this advanced machine utilizes machine vision and AI tools to inspect meat, poultry, and fish with speed and precision.

Unlike factory-raised products, organic meat and poultry exhibit a wide range of variations in size, color, and other attributes due to diverse farming and slaughtering practices. Conventional machine vision systems often struggle to accurately classify visually complex meat products, especially when they are packaged with intricate labels or logos.

Our FoodSense AI Inspector overcomes these challenges by employing sophisticated AI algorithms to analyze and classify food items rapidly and accurately. Whether it’s identifying metal contaminants with X-ray scanning or visually detecting plastic or polystyrene foam, our advanced technology ensures comprehensive food inspection, even in the presence of visually confusing packaging.

With our FoodSense AI Inspector, food manufacturers can maintain the highest standards of quality and safety, safeguarding consumers and enhancing brand reputation. Experience the future of food inspection with our cutting-edge solution, setting new benchmarks for efficiency and reliability in the food industry.

eGG - Fish Inspector

Introducing AquaInspect AI, our revolutionary solution for fish egg inspection, meticulously crafted to redefine quality standards in aquaculture. Leveraging cutting-edge technology and advanced features, AquaInspect AI ensures precise sorting and counting of fish eggs for superior hatchery performance.

Key Features

- Defect Elimination: AquaInspect AI meticulously removes all defective fish eggs, including pin-eyed eggs, glass eggs, small eggs, and pale eggs, ensuring only the highest-quality eggs are retained.

- High-Speed Operation: With a remarkable speed of up to 100,000 eggs per hour, AquaInspect AI maximizes throughput while maintaining precision and accuracy.

- Large Capacity Tank: Equipped with a high-capacity tank, the system accommodates large volumes of fish eggs, facilitating efficient processing.

- Fully Automated: AquaInspect AI offers a fully automated sorting and counting process, minimizing manual intervention and ensuring consistent results.

- Precision Sorting and Counting: Utilizing advanced machine vision and deep learning technologies, the system achieves unparalleled accuracy in sorting and counting fish eggs.

- Adjustable Sorting Discs: Variable size egg sorting discs provide flexibility to accommodate various egg sizes as required.

- Gentle Handling: Correct eggs are delicately removed post-sorting to prevent damage and preserve egg integrity.

- Easy Maintenance: Designed for hassle-free maintenance and cleaning, AquaInspect AI minimizes downtime and maximizes operational efficiency.

- Remote Monitoring: With real-time data and analytics capabilities, the system enables remote performance monitoring and proactive preventive maintenance.

- Reduced Dysfunctional Eggs: By efficiently sorting and eliminating defective eggs, AquaInspect AI helps reduce the percentage of dysfunctional eggs to as low as 2%.

Experience quality assurance in fish egg production with AquaInspect AI. Unlock new levels of efficiency and reliability in your operations with this cutting-edge solution.